Across the country, dry cleaning operations are facing pressure from landlords to become environmentally friendly. Oftentimes, this is because of misleading information based on the dry cleaning practices and machinery from 20 years ago. The truth of the matter is that today’s alternative solvents and machinery leave little impact on the environment and public health. Wet cleaning using water, or systems using steam under vacuum, of course, leave none. So, when your landlord pressures you to change, first try to reeducate him/her. If that fails, explore your “green” dry cleaning options.

Reeducate Your Landlord

Historically, perchloroethylene (perc) was the dry cleaning solvent of choice. Although efficient at degreasing and deodorizing textiles, perc is a carcinogen and classified as a Toxic Air Contaminant by the Environment Protection Agency (EPA). That’s why the 2008 National Perchloroethylene Air Emission Standards for Dry Cleaning Facilities requires a phase-out of perc machines co-located with residential buildings by 2020. The rule also requires all dry cleaners to implement controls on perc emissions. So, if you’re still running with perc, the EPA is not on your side even when you use a closed-loop machine. Your landlord isn’t either. But, if you use an alternative-solvent dry cleaning machine with or without wet cleaning, you can attempt to reeducate your landlord so your business can stay put.

Know the Alternatives

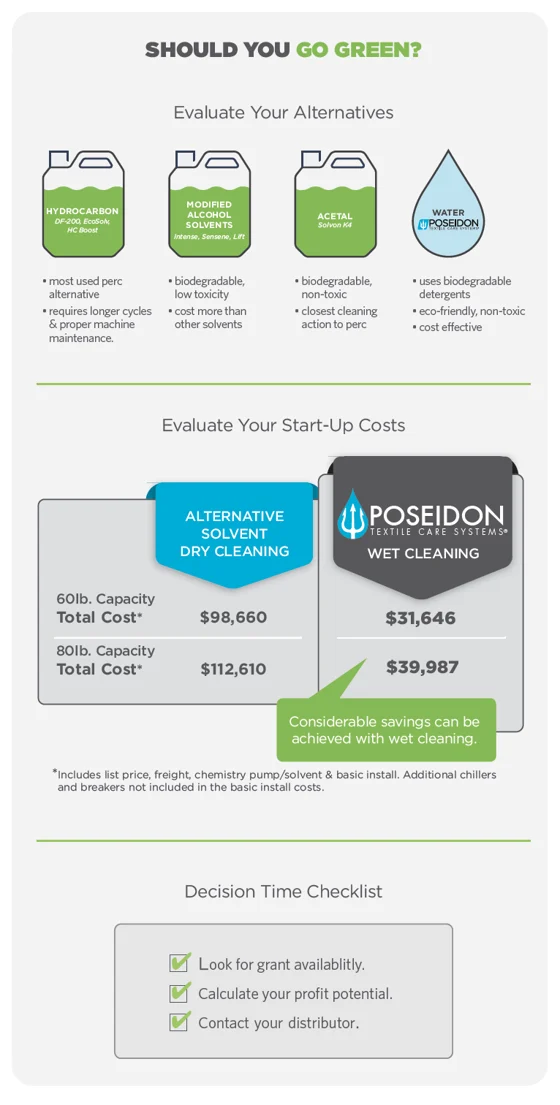

When your landlord won’t budge, evaluate the options because for better or worse perc is on its way out. It used to be that dry cleaners resisted alternative solvents because they did not clean as well as perc. But, that has changed over the years. Today’s most popular solvents, listed below, produce excellent results without the environmental/health hazards of perc.

Hydrocarbon (DF-200 – EcoSolv – HC Boost): Low-odor, petroleum-based combustible solvents with a flash point greater than 140°F. This technology is the most widely used alternative to perc dry cleaning. It works very well on delicate items, and when heated, it becomes a much more aggressive solvent. This alternative requires longer cycles and proper machine maintenance.

Modified alcohol solvents (Intense – Sensene – Lift): Based on modified alcohol formulations that are biodegradable and have low aquatic toxicity. These solvents can be used in hydrocarbon and some multi-solvent machines. They work well for cleaning normal and

delicate items, require short cycle times and involve minimal spotting. These solvents are on the high side, but excel at keeping colors bright.

Acetal (SolvonK4): Halogen-free solvent introduced in 2010. This technology is quickly increasing market share. It’s biodegradable and non-toxic. This alternative has the closest cleaning action to perc so there is very little spotting needed.

As with perc, care must be taken with beading, appliques and other decorations glued onto the garments.

Water (Poseidon): Uses highly programmable wet cleaning machines and new-technology dryers, along with biodegradable detergents and specialized finishing equipment to process delicate garments that would otherwise be dry cleaned. Effective, eco-friendly and non-toxic. Wet cleaning is probably the most cost-effective and thorough way to process textiles, but there is a learning curve and there are proper techniques and procedures that must be followed before, during and after the cleaning process.

Compare Costs

When compared apples to apples, the costs for new alternative solvent machinery is much greater than that of new wet cleaning equipment. Many times, dry cleaners choose to purchase a small-capacity alternative-solvent dry cleaning machine, or a system that uses steam under vacuum, for use in combination with large-capacity wet cleaning equipment. Others choose to exclusively wet clean.

Are Grants Available?

Before you purchase any new equipment, check to see if there are state, county or city grant dollars or tax credits available for changing to alternative solvents or water. California and Washington, for example, both have grant dollars available ranging from $10,000-$20,000.

Decide What Makes the Most Sense for You

Moving away from perc is inevitable. But, you understand your dry cleaning business best. So make new equipment decisions based on your operation’s clientele, staff and profit potential. And, don’t forget to factor in any federal/state/city regulatory requirements and landlord ultimatums. My advice? Contact your equipment distributor to help you sort through the pros and cons.