New technologies allow wet cleaning to significantly improve throughput production over traditional dry cleaning. This makes a strong case for the eco-friendly wet cleaning process. When comparing the costs associated with both — wet cleaning is the clear winner. The initial investment, operational costs and associated fees are thousands less. Read on to see the figures in black and white.

Initial Investment

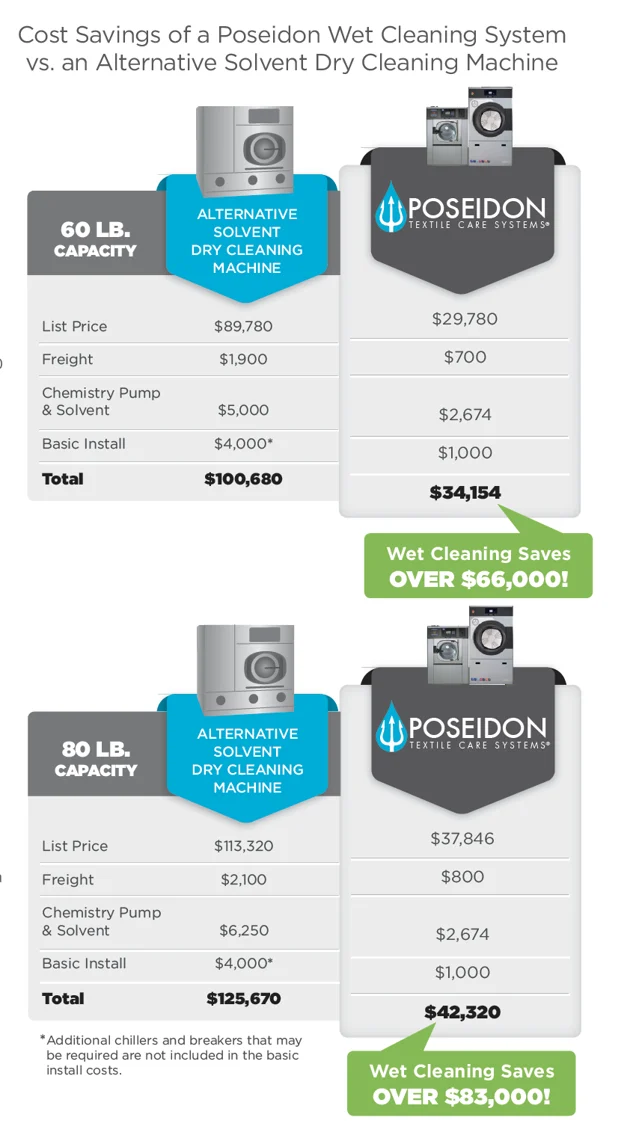

First, let’s evaluate the initial cost of each system. This is the amount required to purchase new alternative-solvent dry cleaning machines versus similarly sized Poseidon wet cleaning systems.

When the numbers are crunched, there’s a $66,000-$83,000 cost differential in favor of wet cleaning. But that’s just the tip of the iceberg. Let’s dig deeper.

Additional Capital Expenditures

Often, there are additional costs associated with operating a new dry cleaning machine, including upgrading boilers, chillers, air compressors and electrical. If you have to upgrade any of these because of your new dry cleaning machine, you’ll fork out considerably more. Whereas, if you go with a wet cleaning system, you won’t.

For example, a customer is installing an 80-pound capacity dry cleaning machine at a cost north of $100,000 list price into an existing facility. To operate correctly, the machine will require the purchase of another chiller ($16,000) and an 80 amp breaker. Additionally, the new chiller will require another 70 amp breaker. In the end, the dry cleaning machine not only requires a new chiller, it demands a costly electrical upgrade. All this adds up.

By comparison, an 80-pound capacity wet cleaning system, which operates on 15 amp breakers, doesn’t require anything extra. Therefore, you’ll likely not have to purchase or upgrade anything else.

Installation Costs & Hassles

Now, consider the installation process for both machines. When you get into larger capacities, installation can get tricky. Let’s say you are installing that 80-pound capacity dry cleaning machine. Because of its large footprint, it won’t fit through a standard 42.5-inch door opening. An 80-pound capacity Poseidon wet cleaning system will.

This makes loads of difference. Recently, we installed an 80-pound capacity dry cleaning machine that would not fit through the doorway. We had to remove the window — along with garment rail systems and counters — to get it inside the plant.

An 80-pound capacity wet cleaning system would have fit through the door and eliminated the need to stop production and remove machinery.

Operational Costs

We know that the minimum initial investment of a 60-pound capacity dry cleaning machine is at least $60,000 greater than that of a similarly sized wet cleaning system. We also know other capital expenditures and upgrades are also part of the installation and operational equation. Now, let’s compare labor, chemistry/solvent, regulatory/licensing fees and utility costs.

Chemistry — Initial start-up costs for chemistry for a 60-pound wet cleaning machine is around $2,674. It’s $5,000 for a 60-pound dry cleaning machine. Not a huge difference, but something that needs to be considered.

Water — Water usage can vary. On the dry cleaning side, when a chiller is utilized to recycle water through a dry cleaning machine, very little water is used. But, a chiller costs between $15,000 and $30,000.

The other way to cool a dry cleaning machine is through the use of a cooling/water tower. These are located on the roof, so they can lose some water through evaporation, and at certain times of the year, can’t be utilized because of high temperatures and extremely high humidity levels. When this happens, plants rely on city water to cool the dry cleaning machines.

In general, a 60-pound wet cleaning machine uses 40 gallons of water per load, and over the course of a year, would go through as much water as a dry cleaning machine hooked to a water tower. A dry cleaning machine hooked to a chiller is the most water-efficient, but this scenario requires a costly initial investment.

Electricity — When it comes to electricity, wet cleaning comes out ahead requiring just 15 amps to operate. A dry cleaning machine requires 60-90 amps.

Natural Gas — Natural gas follows suit. The boiler needed to operate a dry cleaning machine uses 670,000 BTUs, which dwarfs the wet cleaning requirement of 118,000 BTUs. Plus, a boiler will run until all plant production is completed for the day. A wet cleaning system dryer operates in 15-20 minute increments a dozen times a day. Wet cleaning clearly wins.

Labor — When compared, labor costs are very similar in both dry cleaning and wet cleaning.

Regulatory & Waste Disposal Fees

Finally, dry cleaning has regulatory fees and waste disposal costs that vary by state. But, you can be sure there are never disposal or regulatory costs associated with wet cleaning.

On the other hand, Michigan dry cleaners, for example, are inspected annually and licensed through the Department of Environmental Quality (DEQ). They are charged a fee based on the size of the dry cleaning machines in their plants. Additionally, still-bottom-solvent wastes must be picked up and disposed of, which costs hundreds per drum.

Wet Cleaning — a Third of the Cost of Dry Cleaning

When all factors are considered — wet cleaning costs are thousands less than those of dry cleaning. Plus, wet cleaning delivers significantly more throughput. That’s a one-two punch that’s hard to reckon with.

Make wet cleaning a larger part of your plant’s production for less than a third of the cost of dry cleaning and 50 percent more throughput.