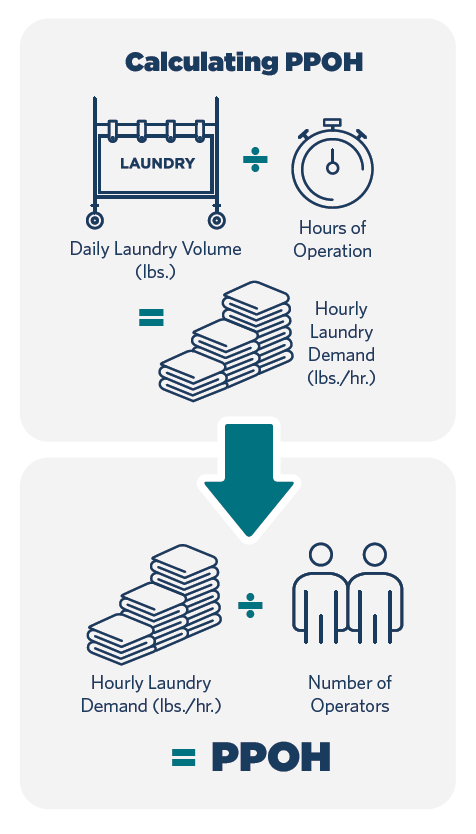

Pounds Per Operator Hour, or PPOH is a critical benchmarking measurement that shows the average laundry pounds processed by a single employee in an hour. It’s likely the most important efficiency metric used by laundry operations. This is because a laundry’s greatest cost savings is always gleaned from reducing the labor hours used to deliver the product. So I urge you, if you haven’t already, to calculate your laundry’s PPOH. Then, look for ways to maximize it.

Maximizing PPOH

There are many things you can do to maximize PPOH, including the improvement of equipment, programming, workflow, employee training and automation, among others. But, you’ve got to determine where you are before you determine where you want to be. Read on for some suggestions …

Step 1: Find out where you stand

Calculate your laundry’s PPOH. Take laundry volume in pounds and divide by labor hours required to perform the work. Divide the resulting number by the total number of people required to produce the product. It might be beneficial to break your laundry out and calculate PPOH by sections — wash/dry line, ironing line, folding and stacking, etc. Then, calculate total PPOH for everything.

Step 2: Make sure your equipment programs are effective

Do an audit with your chemical provider to ensure your laundry uses the correct wash programs to produce your product. Do the same for other equipment — dryers, ironers, folders — with help from your equipment distributor. Make any necessary changes.

Step 3: Ensure operators are using equipment correctly

Reach out to your equipment distributor and ask them to validate that operators are properly using equipment to maximize production. Retrain operators if needed.

Step 4: Benchmark again

After you’ve made cycle, programming and equipment operation changes, calculate your PPOH again. How did it improve? In general, if you are evaluating only the wash/dry/ hand-folding line, a good benchmark is around 100 PPOH.

Step 5: Consider adding automation

Now determine how PPOH might be improved by adding automation. An investment in just one piece of equipment can dramatically improve a laundry’s overall PPOH and product quality. In your PPOH audit you realized that the finishing area — folding and stacking — results in your lowest PPOH. Those are the areas I would focus on first. Sheets and towels are finished in a couple different ways. Towels are washed and dried, then folded. Sheets are washed, then typically ironed without ever seeing the dryer. The next sections will show how automation can impact finishing these two item types, and simultaneously, maximize PPOH.

Step 6: Calculate PPOH again

You’ve done your due diligence, tweaked wash cycles, equipment programs, retrained operators when needed, and installed automation. That means it’s time to calculate your laundry’s total PPOH again. How has that number improved and how does it compare to where you started?

Step 7: Establish your functional benchmark

Now, determine if your recently calculated PPOH is a functional goal for your operation. If your answer is yes, you’ve just established your benchmark PPOH — the number from which you’ll continually work to improve in the coming months and years.