While highly programmable wet cleaning washer-extractors have been on the market for years, their partner dryers have lacked the programmability needed to dry delicate fabrics — wools, silks, linens — without resulting damage. Historically, garments were either wet cleaned and air-dried overnight, which took a lot of time and space, or dry cleaned. Thankfully, emerging dryer technology is changing all that … It’s revolutionizing the wet cleaning process and how textile care operators do business.

Read on to discover what new dryer features and capabilities are now available and how they truly perfect the wet cleaning process — making it quicker and more effective than ever. Simultaneously, learn methods for customizing dryer programs for superior results — leaving garments relaxed, soft and primed for finishing.

Dryer Programmability Matters

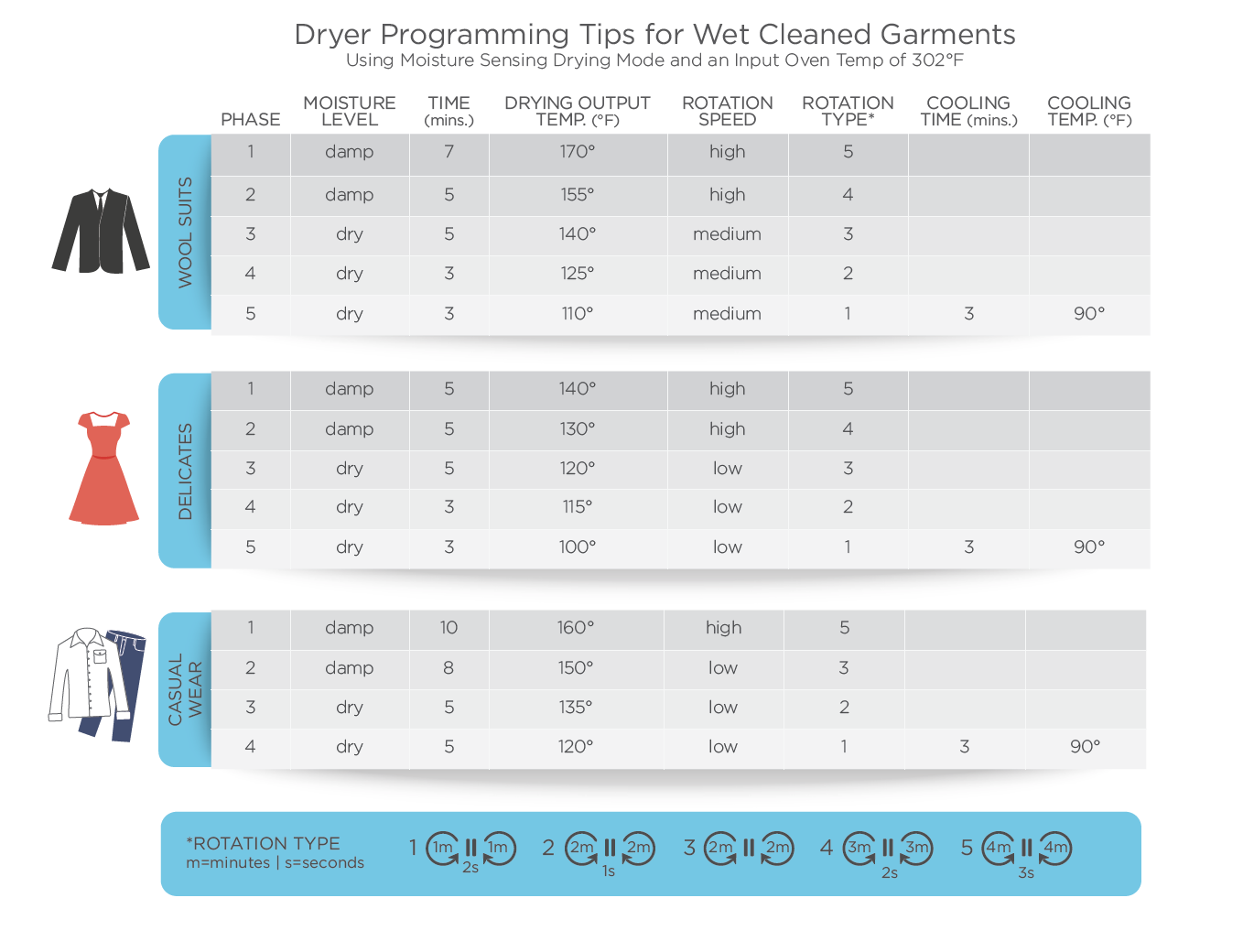

Dryer programmability is finally catching up to the programmability level of a wet cleaning washer. For the first time, there are dryers on the market offering several programmable phases in the drying process, as well as sophisticated control over multiple variables within those phases, including oven temperature, drum temperature, drum rotation action and G-force, timed reversing, and moisture sensing control technology. Many of these drying variables have never been offered before and most have not been programmable.

Productivity, Efficiency & Results

By controlling variables by phase, even the most delicate items can be dried to the proper moisture level that’s ideal for finishing. This means textile care operations can wet clean garments more quickly and efficiently, provide improved customer turnaround times, become more environmentally friendly and lower operational costs. Because the new dryers eliminate air drying, it takes wet cleaning to a whole new level of productivity. Simultaneously, thanks to new dryer technology, the wet cleaning process is 50 percent more productive than dry cleaning and just as effective in ensuring a quality result.

Let’s take wool suits as an example. With a new dryer technology, a load of wool suits takes just 15 minutes to wet clean, 15 minutes to dry and less than 10 minutes to finish. The new dryers make it possible to turn around a suit — from drop off to pick up — in an hour. That cannot be achieved using today’s dry cleaning machines, as they typically mandate a 75-minute cycle before sending garments to finishing.

If the 50 percent wet cleaning production hike isn’t tempting enough, consider the added convenience provided to customers. Plus, the results are as good or better than dry cleaning.

Essential Dryer Capabilities

So, what are the key capabilities to look for? Seek out dryers with the programmability of multiple variables within each phase of the drying process. Programmable phases, beyond the typical dry and cool down, allow for the control necessary to protect garments when they are their most vulnerable — at the beginning of the dry cycle when they are saturated with water and at the end of the cycle when they are near dry. Poseidon dryers, for example, offer up to 11 phases. A minimum of five phases are essential:

Critical Programmable Features

To deliver great results, look for a dryer with the following programmable features within each phase.

1) Drum Rotation Speed (RPMs) & Interval By controlling drum speed and interval, you can remove moisture quickly, without tumbling. This is important. When garments are wet, the drum should ideally spin with enough RPMs to cause garments to cling to the drum, rather than fall and tumble from top to bottom. This prevents damage and shrinkage. Drum speed should be adjustable based on phase, item type, moisture content and fabric.

2) Moisture Level It’s important for a dryer to have the ability to check and confirm the moisture content of a load before advancing to the next phase. Most dryers monitor for one moisture level throughout the entire dry cycle. Now, thanks to new technology, each phase has its own moisture level setting. This eliminates over drying, shrinking and damage at all phases of the drying process.

3) Timed Reversing When the drum only turns in one direction, garments tangle and ball up, creating uneven drying. Look for a dryer with multiple different reversing options.

4) Input (Oven) & Output (Drum)Temperature Most dryers allow control over the drum temperature for a set period of time. But, it isn’t enough. A dryer with programmable oven temperature, from 104-392°F, allows total control over the dryer heat source/flame, which greatly reduces the risk of hot spots and heating inconsistencies that contribute to garment damage or shrinkage. Typically, the oven temperature is higher for thicker materials and lower for delicate garments.

Additionally, new dryers can hit high drum temperatures (up to 195°F) extremely quickly in order to evaporate moisture without as much tumbling. This precise control over temperature, rotation action and drum speed protects garments from damage while allowing the shortest dry times.

5) Time Limit It goes without saying that the duration of each phase is important. New technology allows cycles to advance to the next phase based on time limit or moisture level. A time limit is always programmed to prevent over-drying due to a possible moisture sensing error. This redundancy is an additional safeguard against damaging garments.