When your washers and dryers are aged out or inefficient, it’s time to retool for greater revenue and profit. While planning that equipment retool and comparing brands, ask yourself the following questions:

- Will the new equipment set your laundry apart from the competition?

- Will it attract and serve more self-service customers?

- Will it increase customer turnover for more paying customers per day?

- Will it deliver the flexibility and features you need today and into the future?

In a nutshell, look to replace aged-out equipment with new washers and dryers offering performance, flexibility and customer convenience.

Equipment Performance

Equipment performance is measured by reliability, efficiency and productivity. Choose equipment that offers a quicker wash and dry, for more rapid customer turnover, while saving water, electricity and natural gas.

To do this, look to buy freestanding soft-mount washers. Soft-mount washers have been used for 50 years in high-production commercial and industrial plants. So, don’t confuse these washers with the homestyle, domestic front-load washers in local appliance stores. Commercial soft-mount washers, designed for commercial use, outperform hard-mount washers every time. While both hard- and soft-mount washers are very efficient, soft-mount washers deliver more advantages to positively impact profits.

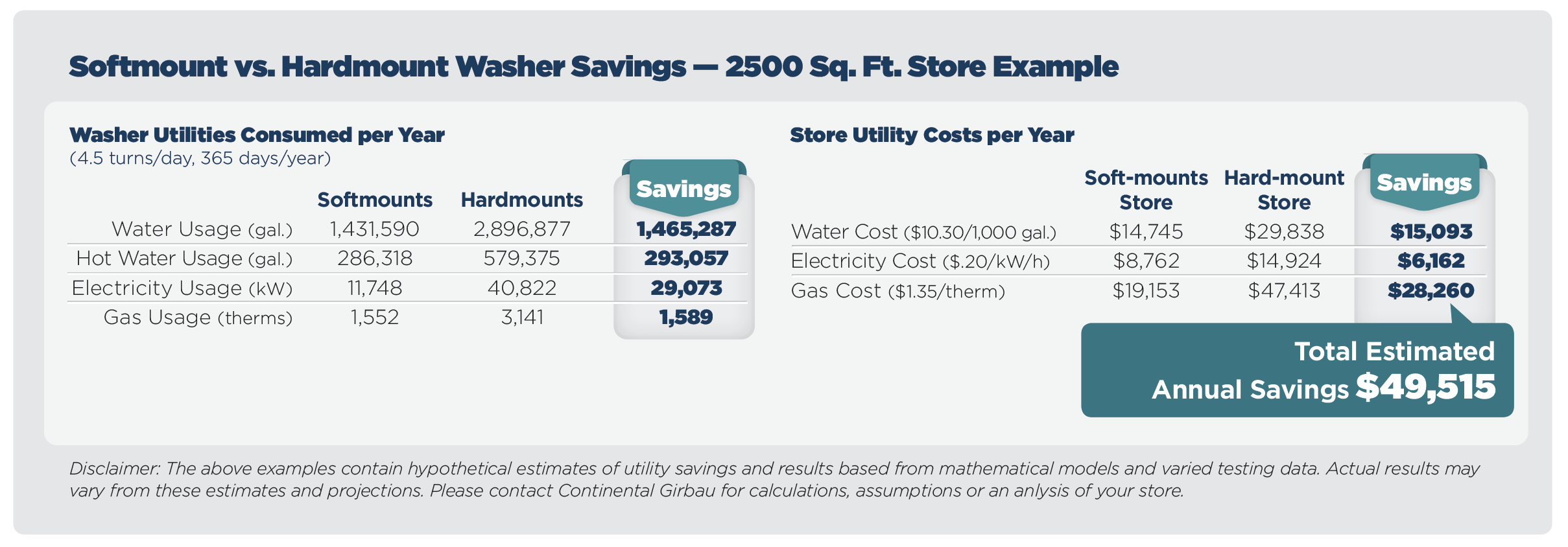

- Long-Term Operational Savings: While the cost of a soft-mount washer is a bit more than a hard-mount washer, it will lower operational costs — especially natural gas usage — considerably. This is because soft-mount washers generate and sustain much higher extract speeds (up to 400+ G-force), when compared with traditional hard-mount machines (100-200 G-force). Thus, they remove significantly more moisture from a load — slashing resulting dry time by up to 50 percent. Soft-mount washers will also reduce the operational time of your dryers — extending their longevity — and cut natural gas costs. A 2,500-square-foot laundry equipped with Continental soft-mount ExpressWash® Washers (up to 400 G-force) will save approximately $49,515 per year in total utility costs, when compared with a laundry outfitted with Continental hard-mount 200 G-force machines. Over six years, $297,090 is returned to a store’s bottom line!

- Improve Customer Turnover: A laundry with softmount washers can serve more paying customers per day — increasing customer turnover — when compared to a store equipped with hard-mount Girbau washers. Even better? Customers save time. They can get in and out in less than 60 minutes! Checkmark for customer satisfaction.

- Easy Install without Bolt-Down: Soft-mounts will also save installation costs and can be placed in the same area of the hard-mount washers they replaced, without the added expense of reinforced concrete foundations ranging from 8 to 14 inches. By installing soft-mount washers versus hard-mount washers, a 2,500-square-foot laundry would save about $5,363 in labor and material costs.

Equipment Flexibility

Machines should offer features and capabilities that bring flexibility to how you operate your laundry. Look for a highly programmable control and the ability to integrate ozone or automatically injected chemistry (detergents, brighteners, microbe kill additives and fabric softeners) into the wash cycle in order to provide sanitization.

- Programmable Control: A quality control allows owners to program virtually any variable of a wash cycle so it’s simple to shorten or extend wash/rinse times, and control water temperatures, extract speeds and vend prices. It also interfaces with payment systems to allow quick and complete control over your machines and laundry.

- Control Upgrades: Do you have the ability to upgrade your control if needed in the future? Some manufacturers provide upgrade kits — keeping your washers relevant.

- Sanitization Capable: Offering customers a sanitized wash is a great way to stand apart, especially as a result of the Covid-19 pandemic. You can sanitize laundry using ozone or chemistry. Be certain your machines are ozone compatible and offer automatic chemical injection because many of them don’t.

- Monetizing Simplicity: Be sure the washer control offers a way to monetize sanitization, or an extra wash or spin. That way when customers select one of these options, they’re automatically charged a bit more in vend price — adding to your profit potential.

Customer Satisfaction

Machines should bring an extra measure of customer convenience and satisfaction to the table. If you’ve checked off the above points, you’re already there. My recommendation? Choose washers with extra wash options, select large-capacity machines, offer sanitization, select soft-mount washers so customers can complete laundry in an hour or less, and provide automatic chemical injection for customer convenience, especially on large machines. This will help set your store apart.

- Soft-mount washers allow customers to complete laundry in 60 minutes of less.

- Washer controls with extra wash options give customers more control over how their laundry is processed.

- Laundry sanitization makes customers feel safe and sets your store apart.

- Big machines allow customers to quickly wash bulky items and family-sized loads.

- Automatic injection of chemicals in big machines eliminates the headache of lugging and loading detergent while providing greater customer turnover during busy times.

At the end of the day, a retool is about generating more revenue and profit, so remember that the equipment buying decision you make today will impact your store for the next 12+ years. Make your equipment choice based on flexibility, performance and customer satisfaction, not simply on purchase price. Utilities are a vended laundry’s greatest uncontrolled expense, so do your research and retool with machinery that delivers now and into the future.

Tod Sorensen is a regional business manager at Girbau North America and vice president of Continental Girbau West, a full-service distributorship serving the Southern California, Arizona and New Mexico vended, on-premise and industrial laundry markets. He holds more than 20 years of experience in vended laundry development and market analysis. Please contact him with any questions at tsorensen@gnalaundry.com or call 866-950-2449.