Seeking new ways to bolster revenue, fabricare professionals are entering the textile restoration market in droves. In doing so, they work with homeowners and insurance companies to clean and restore household soft goods (clothing, window coverings, bedding, towels, etc.) following a flood or fire. The goal? To restore items to pre-incident condition at a fraction of the cost of replacement, and to do it in the most efficient, productive and profitable way possible.

That’s just good business. And thanks to recent advancements in chemicals and dryer programmability, more than 90 percent of contaminated textiles can be restored to pre-loss condition using water. All durable goods, bedding, towels, typical wash-and-wear items, as well as traditionally dry cleaned items, including wool suits, designer silk dresses and wedding gowns, can now be safely wet cleaned.

The good news? Using water — not solvent — is not only less costly and more environmentally friendly, it’s also more productive and efficient. Both are effective restoration methods, but at the end of the day, a textile restoration cleaner will generate more profit using wet cleaning over dry cleaning.

Thanks to today’s technologies, plants can wet clean more quickly and cost-effectively than dry cleaning. Wet cleaning can boost production 50 percent over alternative-solvent dry cleaning. Moreover, wet cleaning outperforms dry cleaning without the negative environmental impact.

A Look at Dry Cleaning

The steps involved with dry cleaning, although effective, are more involved and take more time. In order to restore post-fire textiles using dry cleaning, textiles must be pre-treated overnight in an ozone chamber. The ozone works to remove the odors — something dry cleaning alone can’t accomplish — but adds hours to the textile restoration process. The ozone step is a must for post-fire textiles, but not always a must for post-flood textiles.

After treatment inside the ozone chamber, items are sorted and loaded into a dry cleaning machine that uses solvent, not water, to clean. After another 60-75 minutes inside the dry cleaning machine, the load is removed, finished and packaged.

Using a 60-pound capacity dry cleaning machine, it takes 75 minutes to clean, finish and package 60 pounds of textiles. The total time to completion, including the ozone step, is anywhere from 8 to 12 hours.

More Productive Wet Cleaning

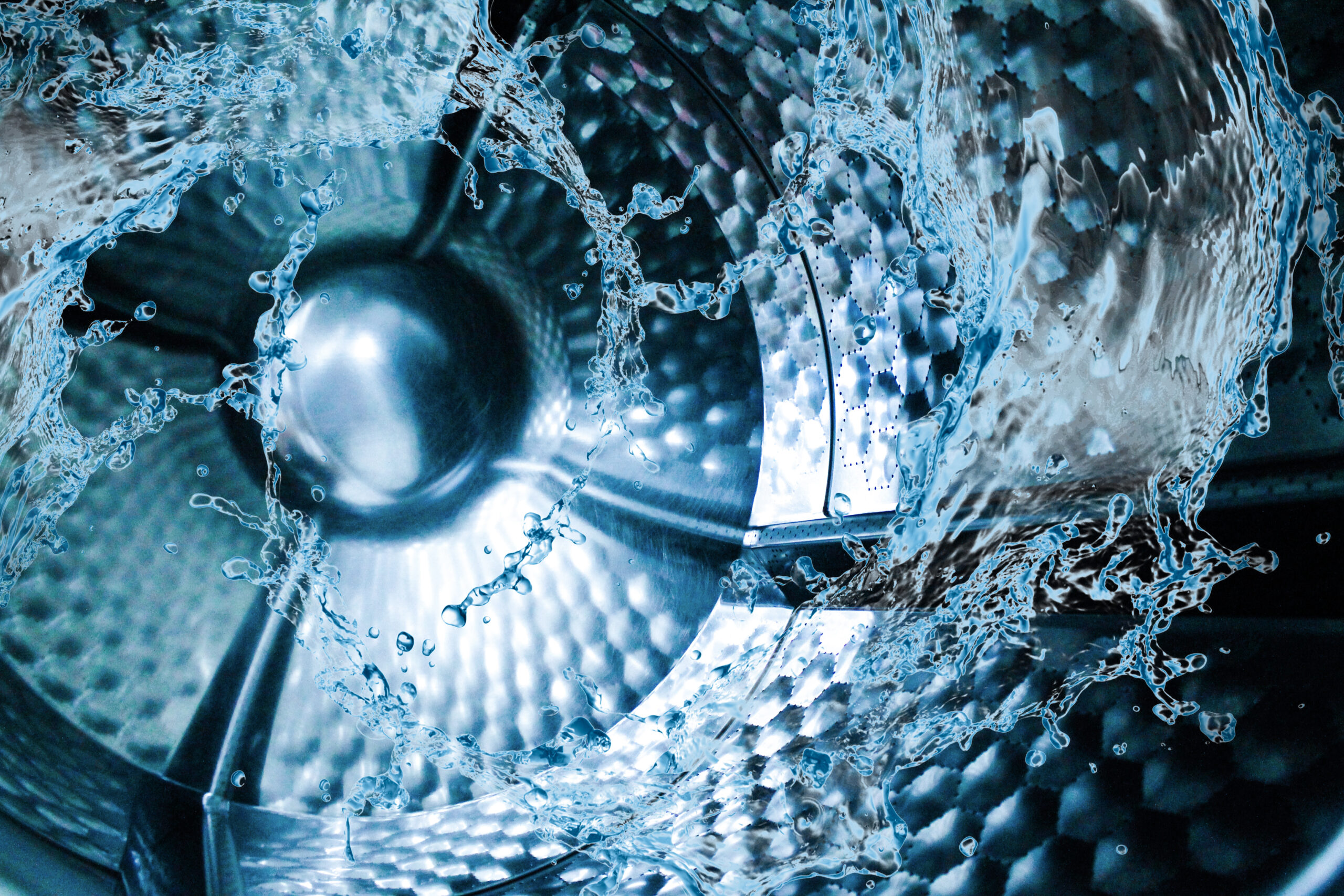

When wet cleaning is used, there is no need to pre-treat with ozone because wet cleaning alone effectively removes the worst odors, including smoke. Instead, textiles are sorted and loaded into a highly programmable wet cleaning machine, which is programmed to automatically combine the right water levels, water temperatures, rotation action, extract speed, number of baths and rinses, and cleaning chemicals. Once the load is complete, after 30-40 minutes, the textiles are loaded into a highly programmable dryer. In the past, it was difficult to dry delicate items, such as silks, wools and linens, without damaging them. But, thanks to new dryer advancements, this isn’t the case anymore. New technology offers phased control over the drying process, and each phase allows programmability of drum rotation speed, drum rotation interval, moisture level, timed reversing, input air temperature, drying temperature, heating temperature, drying time and time limit. In around 20 minutes, drying is complete and textiles are unloaded, finished and packaged.

Using a 60-pound capacity wet cleaning machine and a 60-pound capacity dryer, it takes just 60 minutes to process and finish 60 pounds of textiles.

Apples to Apples Production Comparison

Comparing the two methods side by side, wet cleaning is clearly superior in terms of productivity. Even without the ozone step that’s often required when using dry cleaning, wet cleaning processes are 50 percent more productive than dry cleaning.

Contaminants & Best Practices

Now, let’s determine whether wet cleaning is an effective method for restoring heavily contaminated textiles.

Flood, fire and smoke contaminants pose an immediate danger to human health because they can leave microbes, mold and cancer-causing contaminants behind. Floodwaters often mix with contaminants on the ground, including pesticides, sewage and trash. Even after the floodwaters recede, the microbes and mold that are left behind on clothing and textiles can spur allergic reactions, irritation, gastrointestinal disease, as well as respiratory and soft-tissue infections. Fires, on the other hand, often leave textiles stinking of smoke and infiltrated with an array of carcinogens, particulates and toxic chemicals.

Let’s tackle biohazards, like bacteria and viruses, first.

There are EPA-registered bactericidal chemicals on the market that demonstrate a microorganismal kill rate of 99.9 percent.

In wet cleaning and dry cleaning, these chemicals work in concert with water or solvent, water or solvent temperature, mechanical action and cycle time to significantly reduce or eliminate bacteria, viruses and mold in affected clothing.

Thus, both wet cleaning and dry cleaning are highly effective for removing biohazards. But what about the chemicals, particulates and carcinogens often left behind after a fire?

After conducting numerous scientific studies over the years, the National Fire Protection Agency (NFPA) determined that the most effective method for cleaning firefighter protective gear was by using a highly programmable washer-extractor. The NFPA subsequently published a set of guidelines (NFPA 1851) which detail specifics for cleaning such gear. The synopsis? The NFPA recommends fire departments wash protective gear immediately after exposure to fire. Dry cleaning is not a method recommended by NFPA.

Once gear is wet cleaned, the NFPA recommends that it is air-dried, or dried using ambient air. It can also be dried in a programmable dryer using a no-heat setting and limited rotation. Drying is critical because it provides garments the chance to off-gas and decontaminate further, according to the NFPA.

In a nutshell, the NFPA recommends that firefighter protective gear be wet cleaned, not dry cleaned. Their goal? To keep firefighters safe from fire contaminants.

It seems to me that textile restoration practices should follow the same guidelines — based on scientific research — to keep people safe.

Say Yes to Wet Cleaning

Let’s review the facts. Today, new technologies make it safe to wet clean even the most delicate fabrics. We also know that wet cleaning is as effective as dry cleaning for removing biohazards, and more effective than dry cleaning for removing post-fire contaminants and odor. Moreover, wet cleaning is vastly more productive, which allows textile restoration operations to complete orders more quickly, generate more revenue and provide improved customer service. At the end of the day, wet cleaning should be used to restore the vast majority of household textiles.