Even before a pandemic took the world by storm, athletic programs concerned themselves with fighting and reducing the spread of potentially deadly pathogens, including HIV, Hepatitis and methicillin-resistant Staphylococcus aureus (MRSA), a type of staph resistant to antibiotics. MRSA in particular has been a problem for years — plaguing locker rooms, infecting and ending the athletic careers of many student-athletes and professionals as well. Now with more pathogens occurring, professional, collegiate and high school athletic programs and teams are taking extra precautions, even when it comes to processing laundry. Their goal? To properly clean and sanitize athletic laundry to stop the spread of disease, while preventing contamination from soiled laundry to equipment managers, staff and the athletes.

Key to this endeavor is the disinfection (kills 100 percent of pathogens) of hard surfaces, proper laundry handling and sorting, and thorough cleaning and sanitization (kills at least 99 percent of pathogens) of everything from loops, towels, helmets and pads, to uniforms, personals, warm-ups and coaches attire. In this article, I’ll overview laundry operation best practices for ensuring that pathogens do NOT spread to others.

Wear Personal Protective Equipment

Persons collecting, sorting and folding laundry should wear masks and gloves, while maintaining distances of 6 feet. Soiled laundry can expose laundry operators, who are often student-athletes, to pathogens that can make them sick. Ensure they are properly protected with gloves. Even aprons aren’t a bad idea. Similarly, once laundry is cleaned, they should wear clean gloves when handling and folding it. After every shift, good handwashing is also critical.

Visibly Clean Surfaces with Soap and Water

Cleaning hard surfaces with soap and water reduces the prevalence of pathogens and is completely safe. Do this before you disinfect.

Disinfect Hard Surfaces and Remove Soft-Surface Items

Use Environmental Protection Agency (EPA)-registered disinfecting products on folding tables, laundry bins, countertops, floors, machinery, and high-touch areas like door knobs, handles and key boards. Find these products listed at www.epa.gov. For disinfection of hard surfaces, Terry Hammond, national sales manager at chemical provider UNX Industries Inc., recommends Sanix, a one-step cleaner and disinfectant. “Sanix is an EPA-registered product that disinfects, cleans and deodorizes in one labor-saving step,” he said. A multi-purpose, neutral pH, germicidal detergent and deodorant, Sanix is highly effective against a variety of pathogens including, HIV-1, Escherichia coli (E. coli), Salmonella Typhimurium, Staphylococcus aureus, the novel SRS related Coronavirus (SARS-CoV-2/COVID-19) and the Human Coronavirus,” said Hammond. Another option, according to Brian LaBarbera, research chemist for Sports Chemical Group, is REEKOUT, a disinfectant that also helps eliminate smells in equipment and laundry. “Stealth Industrial Sanitizer is also a nice product because it’s FDA-registered and duals as a hand sanitizer,” said LaBarbera. Once you settle on the right products for your facility, be certain to follow directions on the container. The “dwell time,” or amount of time disinfectant is left on a surface, is critical, according to Hammond. When EPA-registered disinfectants are not available, alternative disinfectants can be used (for example, 1/3 cup of bleach added to 1 gallon of water, or 70 percent alcohol solutions), according to the EPA.

Launder Using a Highly Programmable Washer

Both Hammond and LaBarbera also recommend using a programmable washer, such as a Sports Laundry System® (SLS) Washer, with automatic chemical injection functionality. That way, technical cleaning and disinfection programs can be set up for towels, uniforms, loops and practice gear. Operators just load the washer, select the appropriate program number and press start. The machine automatically adjusts water temperature and levels, number of baths and rinses, with the perfect chemistry/ozone, rotation action and cycle time. This ensures a load of uniforms is cleaned exactly the same way no matter who is operating the washer — reducing human error and eliminating damage to expensive uniforms and fabrics. Moreover, some laundry systems, like SLS, offer programmable quarter- and half-turn rotation options — making it easy to clean and sanitize bulky items such as pads and hockey gloves.

Ensure Sanitization of Athletic Laundry

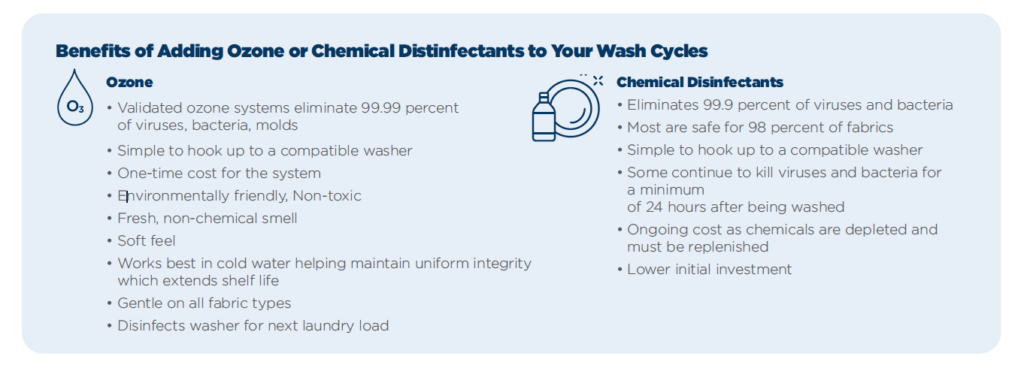

To ensure athletic laundry is sanitized, ozone or an EPA-registered chemical sanitizer additive must be automatically injected into your highly programmable washer. Your chemical representative will ensure this by properly programming your washer(s) by item type. SLS washers, for example, work with both ozone and/or chemistry to accomplish disinfection. Both ozone and any chemical disinfecting/ sanitizing additive should be automatically injected into the washer at the appropriate time and water temperature in the wash process. In order to choose from these sanitization additives — chemistry or ozone — you must first understand the differences between the two.

What’s Ozone and How Does it Work?

Ozone (O3) is a powerful cleaning agent that works best in cold water. It’s the third oxygen atom of ozone that attaches to, and breaks down organic materials in the wash, including soils, viruses, bacteria and molds. Once broken down, these materials are easily removed from fabrics during the wash cycle. Ozone systems are easily installed via a connection to a compatible washer. Ozone is eco-friendly and works in concert with automatically injected detergents and softeners to clean and sanitize athletic laundry. When choosing an ozone system, be sure it validates the levels of ozone in the wash, warns Brett Daniels of Aquawing Ozone Systems. “The ozone system you select should automatically adjust ozone levels according to the soil content of the load and validate that sanitization is achieved,” he said. “Not all ozone systems do this, but it’s critical in order to eliminate pathogens like MRSA.” Aquawing Ozone Systems produce a 99.99 percent kill rate, according to Daniels.

What’s a Chemical Sanitizer and How Does it Work?

If ozone isn’t an option, laundries can also sanitize a wash load using an EPA-registered chemical sanitizer that’s added to the wash cycle. Like ozone, these work in combination with automatically injected detergents, detergent fabric boosters and sours. A chemical sanitizer’s sole purpose is to kill close to 100 percent of the pathogens and molds found in laundry, including MRSA. Moreover, a programmable washer with automatic injection capabilities is easily connected to a dispensing system provided by your chemical representative. LaBarbera recommends using a color-safe bleach additive. “Just one ounce of color-safe bleach to every 10 gallons of water is the proper parts-per-million to kill any bacterium or virus,” he said. Color-safe bleach is safe for use on 98 percent of all fabrics. Hammond, on the other hand, recommends Vanguard, an EPAregistered laundry bacteriostat/sanitizer that’s safe for any fabric type. “Vanguard kills 99.9 percent of all pathogens and offers residual efficacy for a minimum of 24 hours on garments washed or processed with it,” he said.

The Choice is Yours

At the end of the day, the important thing is that proper PPE is used, surfaces are disinfected, and athletic laundry is sanitized to keep athletes, coaches and staff safe. It’s up to you and your athletic program to decide whether that’s accomplished using a highly programmable washer with a combination of automatically injected detergents and ozone, or one using a combination of detergents and a sanitizing chemical additive.

As Sports Laundry Systems® national sales manager, Steve Leib fully understands athletic laundry processing and disinfection. As such, he knows the threat that pathogens, like MRSA, pose to student athletes and athletic programs. In this column, he outlines how to properly handle and process athletic laundry in order to prevent the spread of such infections.